We are Schmitz Foam

Your expert partner in XPE foam

Schmitz is a fourth generation family business that was established in 1935 in the Netherlands. We recycle foam residues and process them into new high-quality foam products. In 2017, we opened a second, brand-new state-of-the-art production plant in Coldwater, MI.

Our divisions

At Schmitz Foam, we are committed to innovation, sustainability, and quality across three specialized divisions.

Watch our

corporate video

We're thrilled to unveil our brand new corporate video, showcasing our passion for foam and sustainability. Discover our expertise in foam recycling and witness how we upcycle foam residues into brand new products.

▪ Schmitz Foam Products

Experts in high-quality shock pads

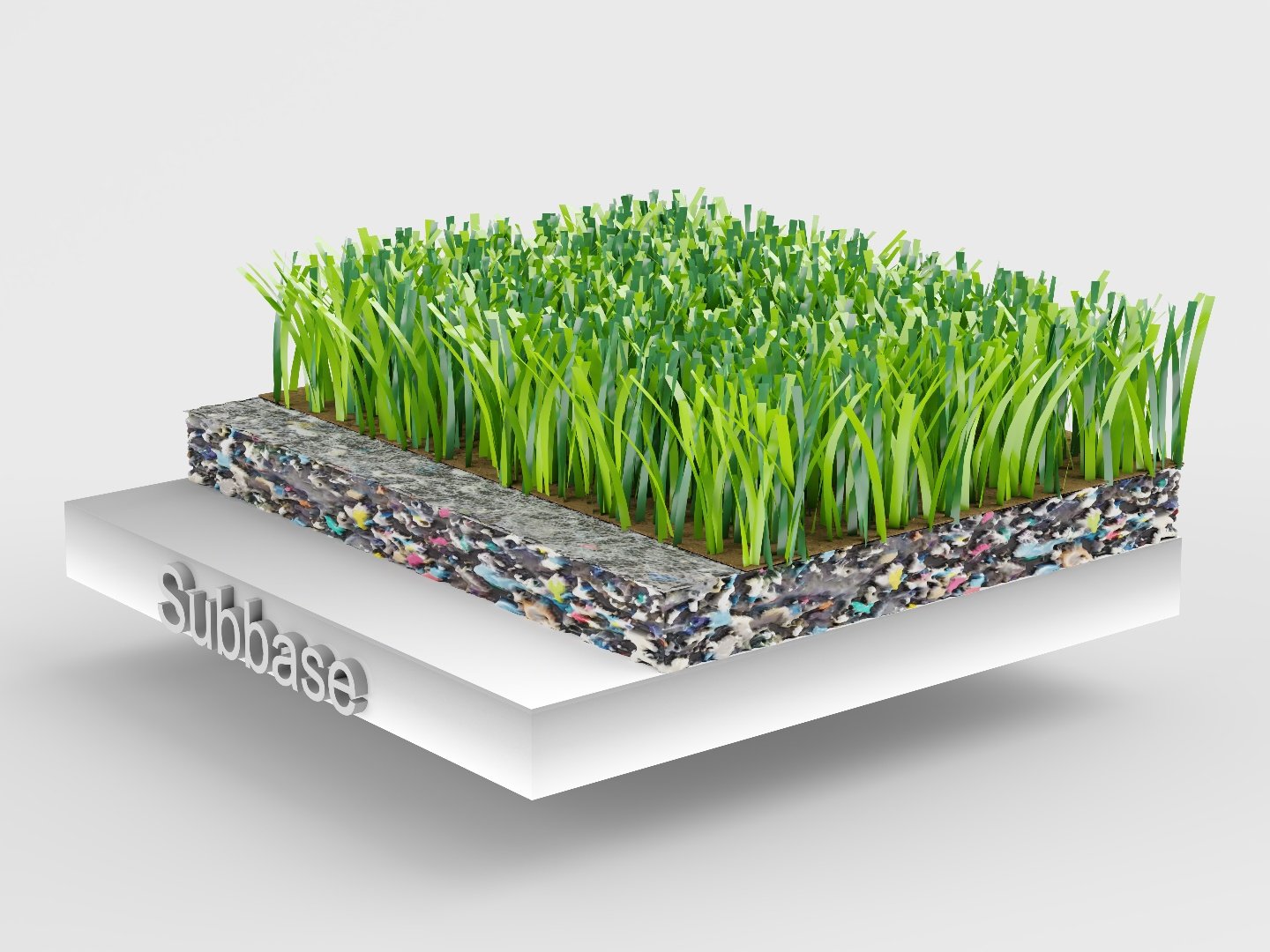

ProPlay shock pads are sustainable and form the perfect base for artificial turf systems for sports fields and playgrounds. The first ProPlay shock pad was produced in the Netherlands in the early 1990s and has since been the only shockpad that combines top performance with superior drainage capacity. In 2017, we opened a second, brand-new state-of-the-art production plant in the United States.

ProPlay: the shock pad that has it all.

▪ Schmitz Foam RecyCling

Experts in XPE Foam Recycling

Since 1990, we successfully give XPE foam residues a second life. Thanks to our recycling process our partners worldwide save elimination costs and avoid environmental damage. Together with our partners, we make sure that no foam goes to waste.

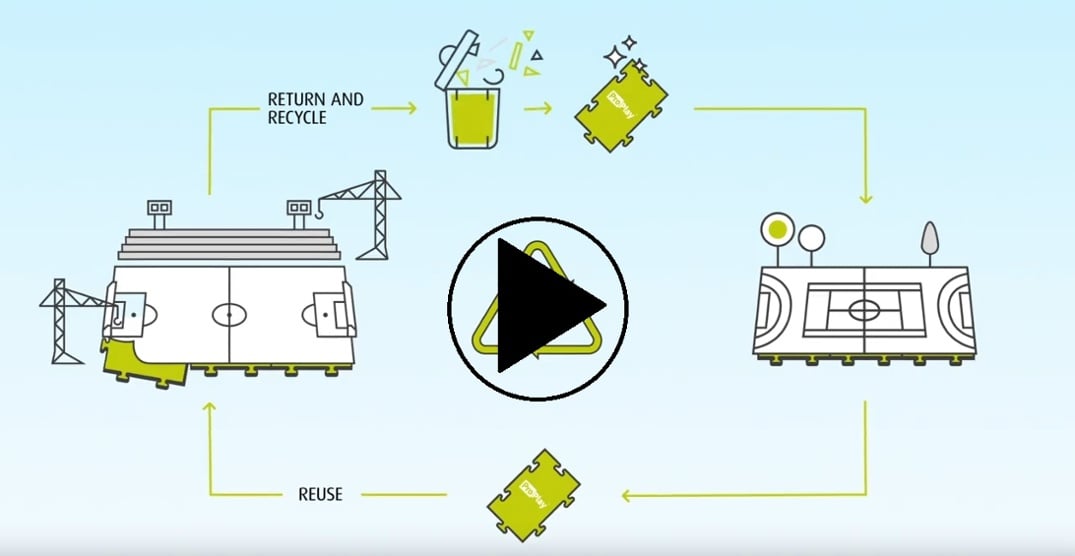

The continuous loop of giving foam a purpose.

▪ Schmitz Foam Supply

Experts in XPE Foam Supply

Our newest division Schmitz Foam Supply saw the light of day in 2022. It is the year we started producing and supplying first-class XPE foam. RoFoam® is a flexible, lightweight, and durable XPE foam for a wide variety of applications.

RoFoam, first-class XPE foam.

.png)

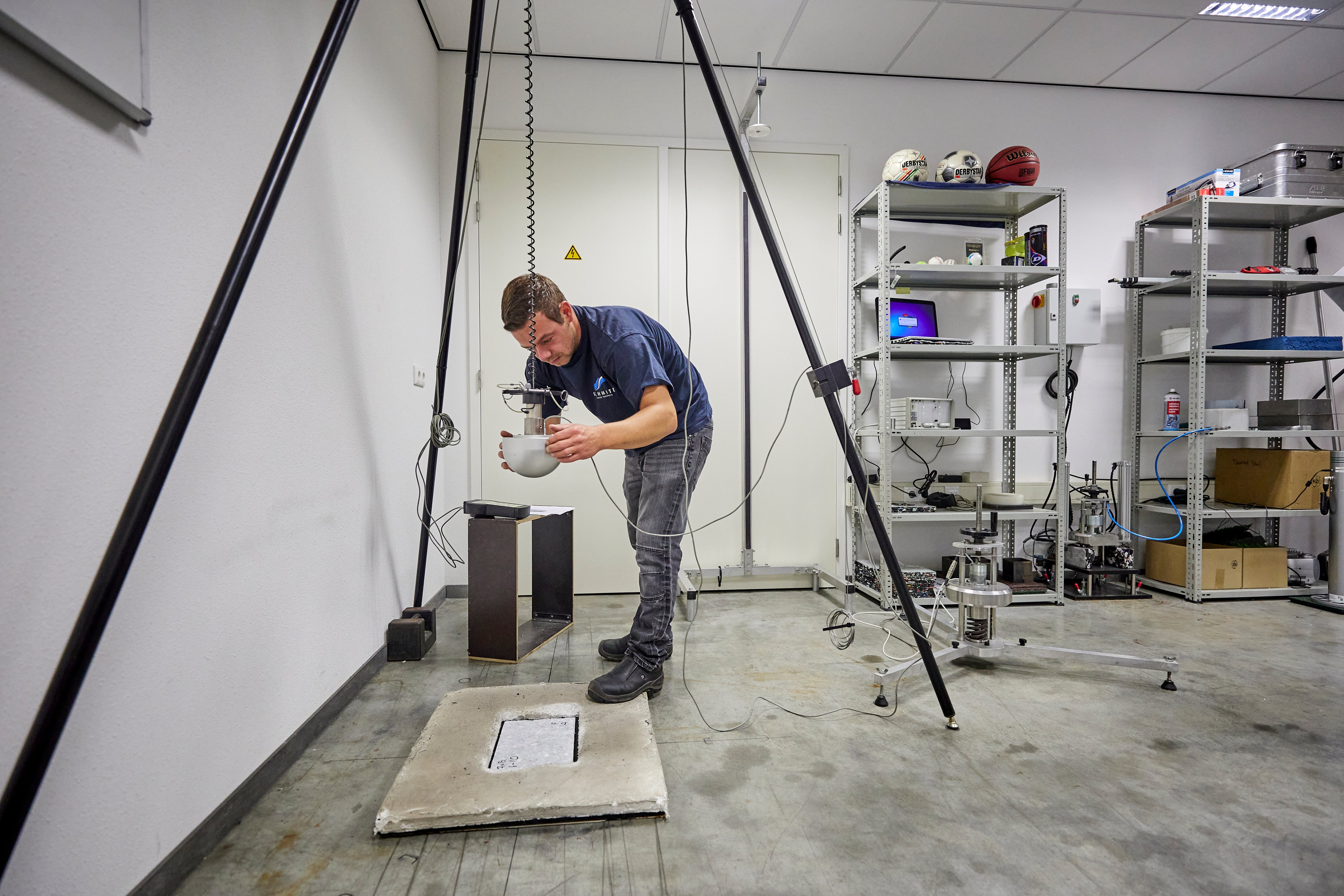

Consistent high-quality to build on

Quality is at the core of what we do, and embedded through our entire organization. Both our plants in the Netherlands and the US are ISO 9001 certified, and that’s for a reason. We invest heavily in having our processes and products tested to ensure every pad meets our rigorous quality standards. Each plant has a comprehensive onsite testing laboratory to test our product characteristics, but also performance. That is what makes the difference in any project application.