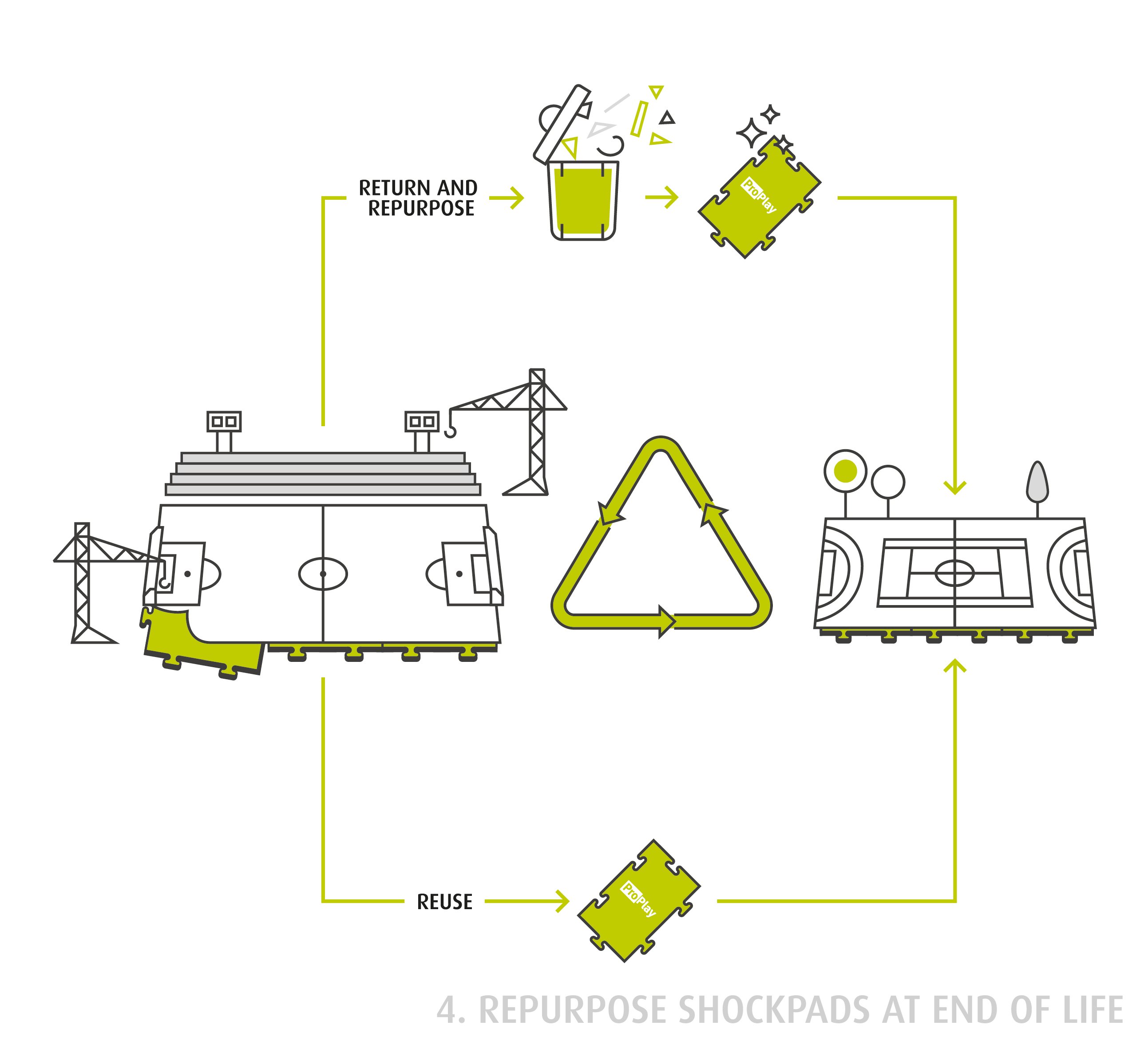

When a ProPlay shock pad is no longer needed for its original application, the material can always be reused in another sports field or playground or recycled for use in a pad for another purpose.

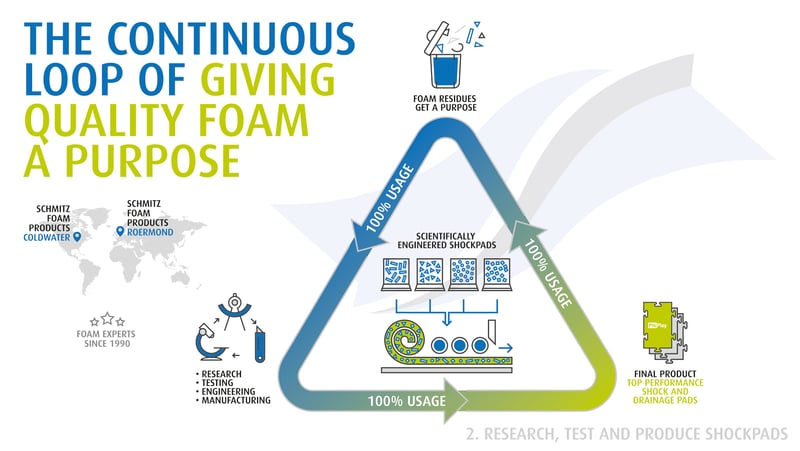

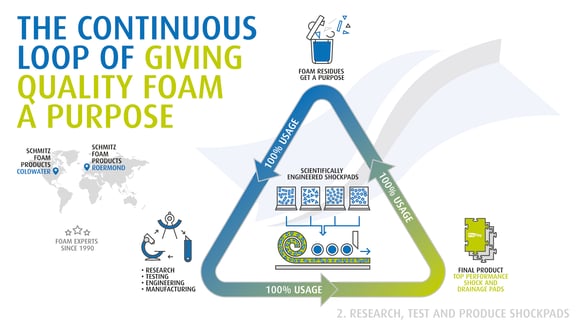

The continuous loop of giving quality foam a purpose

The continuous loop of giving quality foam a purposeAll ProPlay products are made of quality foams that no longer have a meaningful purpose in their particular industries. These foams come from industries such as the automotive, packaging, sports and leisure and construction industries. By giving these foams a purpose, Schmitz Foam Products prevents them from ending up in landfills or incinerators, which consequently reduces the need for fossil fuels for the production of new virgin foam. When a ProPlay shock pad is no longer needed for its original application, the material can always be reused in another sports field or playground or recycled for use in a pad for another purpose.

Schmitz Foam Products sources the quality cross-linked polyethylene foam from all major foam producers and converters worldwide. The characteristics of their cut-offs, left-overs and unsold products provide the perfect raw material for high-quality shock pads and drainage pads. The closed-cell foam doesn’t absorb water and remains flexible in any climate and regardless of its intended purpose. It does so for a very long period.

The Schmitz Foam Products’ recycling philosophy aims to find a new, long-term use for its shock pad whenever possible and before recycling is considered as an alternative. The company will go to great lengths to see whether ProPlay sheets that have been reclaimed can still serve a purpose elsewhere. Tests are conducted to establish the performance and quality of the sheets and to determine whether they could serve another purpose in a sports field or, perhaps, should be used in multi-game areas or for other drainage or shock-absorbing purposes. Only once it is established that this is not the case will the ProPlay sheets be recycled.

When it is not possible to find a new use for the original shock pad it can be returned to Schmitz Foam Products for recycling to a brand new pad for a variety of applications. Sports governing bodies are strict regarding the constant technical performance they expect the material to deliver. Something we can only encourage as we aim for the highest possible performance of our products. Therefore, our recycled product can perfectly serve other purposes like drainage mats for roof gardens.

Due to its lasting performance, of which it has been established that it will last for at least 25 years, it is understandable that Schmitz Foam Products has only been offered few a ProPlay pads for recycling. Most of ProPlay pads are still performing well as part of artificial grass systems. Nevertheless, giving used ProPlay sheets a new lease of life is something that can be done multiple times as the performance degradation is very limited. Much of the ability to extend the lifespan of the foam can be attributed to Schmitz Foam’s long-time experience and extensive knowledge of polyethylene foams and a dedication to only one thing: shock pads!

In case your fields situation is as such that it is desired to transfer (rain)water to the sides of the field, the ProPlay-Sport D-version provides the solution. This shock absorbing pad with built-in horizontal drainage channels can be installed without an impermeable liner if you want to benefit from both its vertical ánd horizontal drainage capabilities. In case vertical drainage is not wanted, you simply need to install our D-version with impermeable foil. By providing the field horizontal water drainage capabilities you can accomplish a great saving in both time and costs to take away the need for digging out the entire subbase.